Commitment to Fabric

About “Wakaba”, hamamonyo’s special fabric

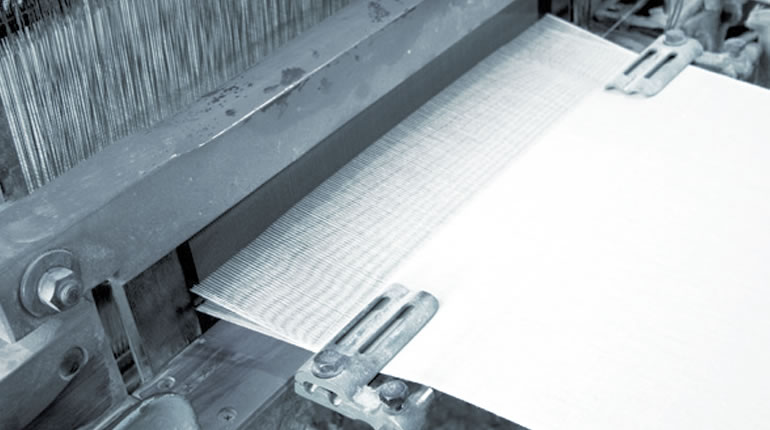

hamamonyo’s tenugui use a special fabric called “Wakaba”, woven especially for our tenugui.

“Wakaba” is made at a special affiliate factory, but since each loom has its own idiosyncrasies, and each artisan their own idiosyncrasies even when using the same loom, the final product varies depending on the weaver.

4 rolls of “Wakaba” can be made per loom per day, taking nearly 16 hours.

10 minutes on the loom at last produces enough material for 1 tenugui.

Since the loom is stopped if even just one thread breaks during weaving, this work requires meticulous attention to detail.

Features of “Wakaba”

The thread count of “Wakaba” is even higher than that of “bun”, a typical tenugui fabric.

Both warp and weft have high thread count, and where bun has a warp thread count of 650, Wakaba has a warp thread count of 680.

Currently, yarn counts for typical tenugui are roughly 20 or 30, and with a yarn count of 20, “Wakaba” is relatively thick.

*The higher the yarn count, the finer the fabric

The thickness and count of the thread could be thinner or higher, but “Wakaba” has been designed with the optimal balance to bring out the texture of hamamonyo’s tenugui.

hamamonyo’s Commitment to Domestic Thread

The threads used to make tenugui fabric can be found in such places as Pakistan or China, yet “Wakaba” is committed to using domestic thread.

We use relatively strong thread for the warp, and thread of superb strength for the weft so that, even if the weft shuttle is skipped, the threads do not twist. Thread that is too strong will produce strong twisting as well, and when thread that is twisted and slack is woven as is into fabric, the fabric will start to form balls (nep).

Of course, this is unchanged for the warp and weft of domestic thread as well.

Thread from overseas contains higher rates of impurities (such as clothing threads) at the cotton purification stage, and while this is not apparent when weaving the fabric, when bleached and washed, parts of the fabric turn red or blue, which can affect the dyeing process later on.

At hamamonyo, we are particular about our special fabric, made with domestic thread for optimal dyeing.

About the Width of Wakaba Fabric

Since this tenugui fabric is produced by hand, there are slight differences in width.

Also, the subsequent bleaching process shrinks the fabric roughly 2 cm.

We hope you will enjoy these irregularities in the width of the fabric as part of the “flavor” of a handmade product.

hamamonyo’s “Eco-Bleaching”

At hamamonyo, we take the environment into consideration by using “Eco-Bleaching”.

Bleaching is a process that removes the oils and dirt originally found in the cotton and adhesives of the thread using various chemicals and hot water washes to make it easier to dye later on. Wakaba uses an environmentally friendly bleaching process called “Eco-Bleaching” that is dedicated to improving quality.

Bleaching involves several processes, including removing adhesives, refining, and whitening.

This process generally uses caustic soda, hypochlorite, sulfuric acid, and many other chemical products containing chlorine. While these are washed off or neutralized, there is no positive proof that all residual substances have been eliminated.

“Wakaba” gets its whitening results with its unique “Eco-Bleaching”, which does not use caustic soda or hypochlorite.

Since Eco-Bleaching does not have a strong whitening effect, the product does not turn pure white and thus requires a high level of craftsmanship in dyeing afterwards; however, it suppresses hazardous liquid wastes and emissions, minimizing the water treatment burden as well.

hamamonyo’s “Wakaba” is an environmentally-friendly fabric that brings out the features of the original fabric.